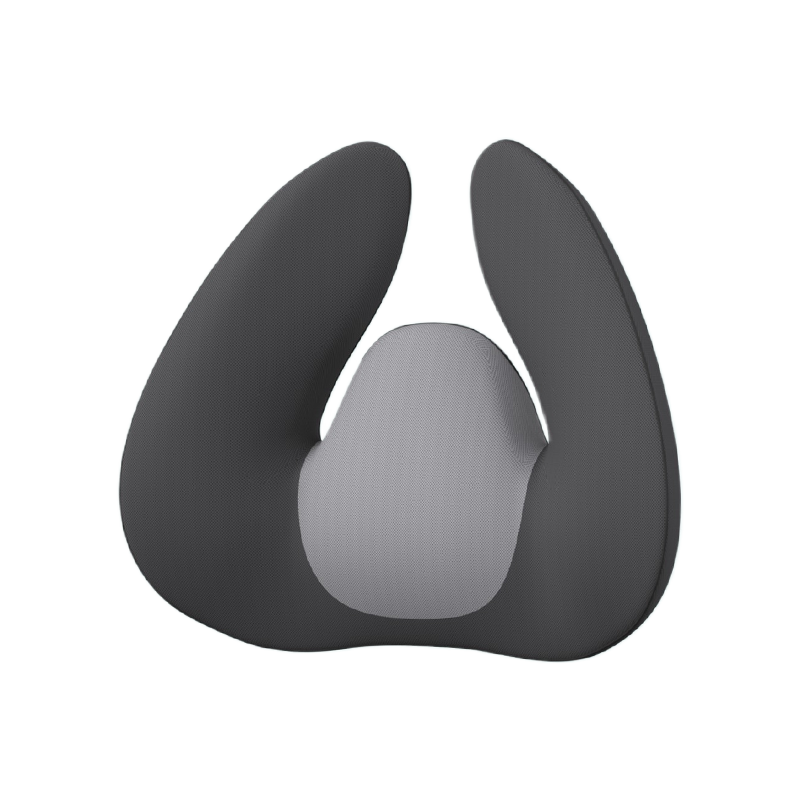

The performance of memory foam pillows is closely related to its density and vent design. These two factors reshape the support, comfort and health attributes of the pillow through physical properties and structural innovation.

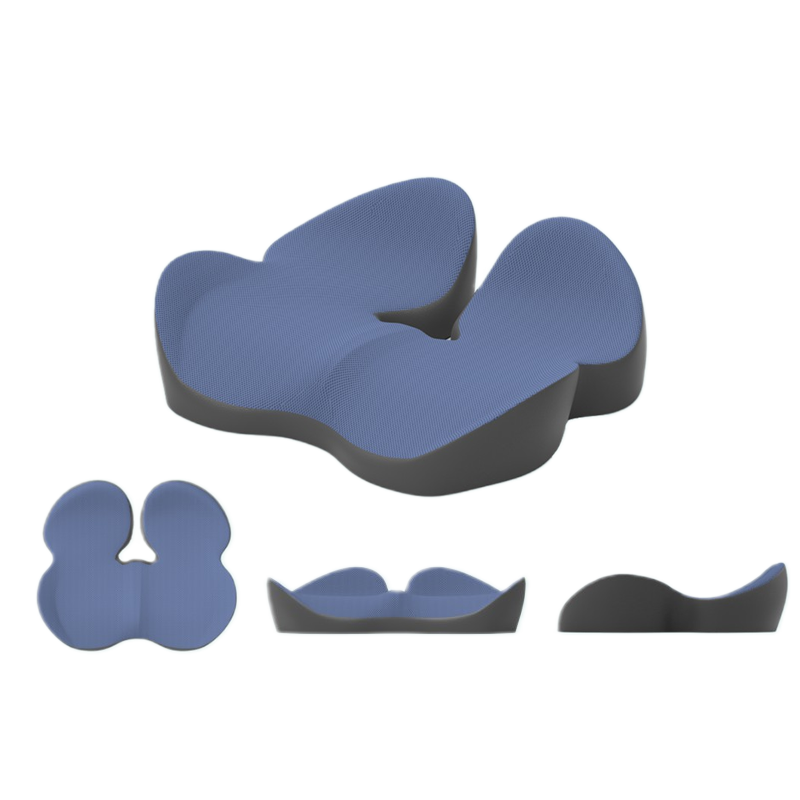

The density of traditional memory foam pillows usually directly affects its mechanical performance. High-density sponges have stronger support and faster rebound speed, which can effectively maintain the physiological curvature of the cervical spine, especially suitable for side sleepers or patients with cervical spondylosis. This pillow is made of high-density memory foam material, which can quickly sense body temperature and pressure, allowing users to enter deep sleep faster, thereby effectively improving sleep quality. It conforms to ergonomic principles, can accurately fit the contours of the head, neck and shoulders, and evenly disperse pressure. In addition, low-density sponges are more susceptible to temperature and soften due to their loose pore structure, which may aggravate the stuffiness and affect sleep quality in summer. High-density products reduce temperature sensitivity through a tight molecular structure, and non-temperature-sensitive memory foam can maintain a stable hardness at 10-40℃, suitable for use in all seasons.

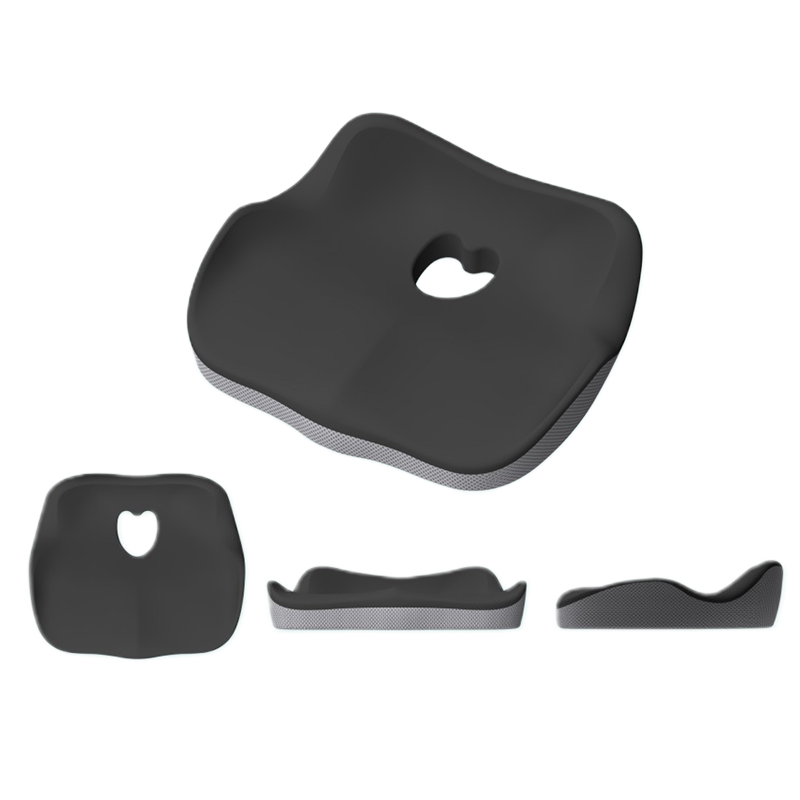

The thermal conductivity of traditional memory foam is only 0.038W/m·K due to its closed-cell structure, so it is easy to store heat to above 37°C. The ventilation hole design forms an air convection channel through honeycomb openings, which reduces the temperature of the pillow surface and improves the humidity control ability compared to ordinary pillows, effectively alleviating the problem of night sweating. Combined with the slow rebound characteristics of memory foam, the ventilation holes can reduce the "sinking feeling" of the head.

English

English عربى

عربى